Introduction: Power engineering DC power supply equipment, as the security power supply and control signal power supply of the main electrical equipment, is a very large multi-branch power supply network. Under normal circumstances, one-point grounding does not affect the operation of the DC system, but if the grounding fault point cannot be quickly found and repaired, another grounding fault occurs, which may cause major faults.

There are two main methods for traditional detection of DC system insulation: bridge balance method and low-frequency detection method. But both have some insurmountable flaws.

Therefore, as early as 2004, the China Electric Power Research Institute officially released dl-t856-2004 "Specifications for DC Power Supply Monitoring Devices for Electric Power" in the appendix a.3.g of the article, which clearly stipulates: "The number of detection feeder branches should be greater than 32 , the use of sensors, should reduce the influence of branch capacitance, easy installation".

This paper discusses the scheme of leakage current sensor used in branch leakage current detection, and proposes: (1) The importance of intelligent self-checking function to a safety monitoring device. (2) Intensification, modularization and miniaturization will be the future development direction of power engineering DC power supply equipment.

1. Review of traditional methods mainly include bridge balance method and low frequency detection method

1. The insulation monitoring device realized by the bridge balance method is widely used, but it cannot detect the situation when the positive and negative insulation of the DC system are equally reduced; even if the insulation monitoring device alarms, it cannot directly obtain the insulation resistance of the system to the ground.

2. The grounding resistance that can be detected by the low-frequency detection method is restricted by the distributed capacitance of the DC system to the ground, and the low-frequency AC signal is easily disturbed by the outside world. In addition, the injected low-frequency AC signal will increase the voltage ripple coefficient of the DC system.

To sum up, both the traditional bridge balance method and the low-frequency detection method have some insurmountable defects.

2. Feeder branch leakage current detection scheme

1. Leakage current generation in feeder branch

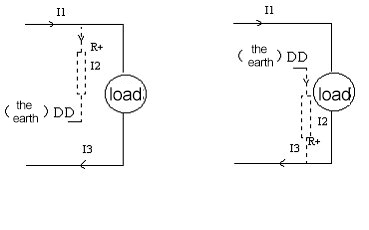

When both positive and negative insulation are reduced, there will be a significant disproportionate leakage current in the line. As shown in Figure (1) below.

As the insulation of each branch is further reduced, the leakage current will also increase disproportionately. If the magnitude of the leakage current cannot be detected in time and accurately, and an alarm signal is given at the preset safety threshold point, it will bring great security risks to the entire power system.

2. General scheme of feeder branch leakage current detection

According to paragraph a.3.g of appendix a.3.g of dl-t856-2004 "Specification of DC Power Supply Monitoring Device for Electric Power", it is clearly stipulated: "The number of branches of the detection feeder should be greater than 32, and sensors should be used to reduce the influence of branch capacitance, and the installation is convenient. "

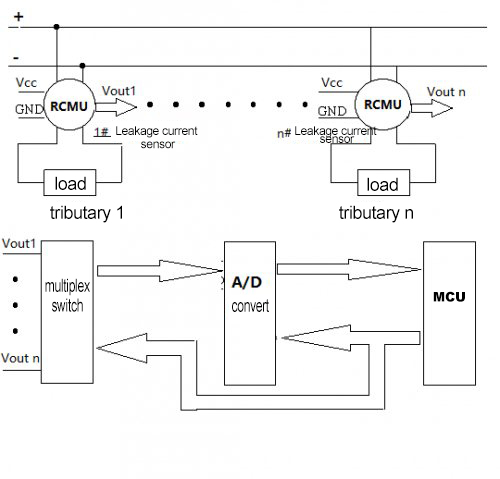

Figure (2) shows the general structure of the branch insulation detection scheme

figure 2)

The single-chip microcomputer collects the output voltages of different branch leakage current sensors through multiple switches, and sends the collected data to the main module when the insulation main module needs it.

It can be seen that the leakage current sensor is the decisive device.

3. Discussion on the selection of leakage current sensor

1. At present, the leakage current detection of feeder branch mainly uses the scheme of DC leakage current sensor. As shown in Figure (3) below:

image 3)

It can be seen that the current DC leakage current sensor: rail type installation, thread type measurement, large volume.

A detailed review of the relevant specifications of a mainstream application model and the actual use process found the following deficiencies:

· Accuracy, poor linearity

· High power consumption

The temperature drift is high, and the working temperature range is narrow, and it can only work between -10 and 70 degrees

· Slow response time

· Only DC component can be measured

The module volume is large, which is not conducive to the development of modularization and digitalization

There is no self-checking function, and the maintenance and troubleshooting costs are huge

2.RCMU

Under the background of intelligent, intensive, modular and miniaturized industrial upgrading, it is a trend to reduce the size of the current power engineering DC power equipment, improve energy density, reduce costs and improve efficiency.

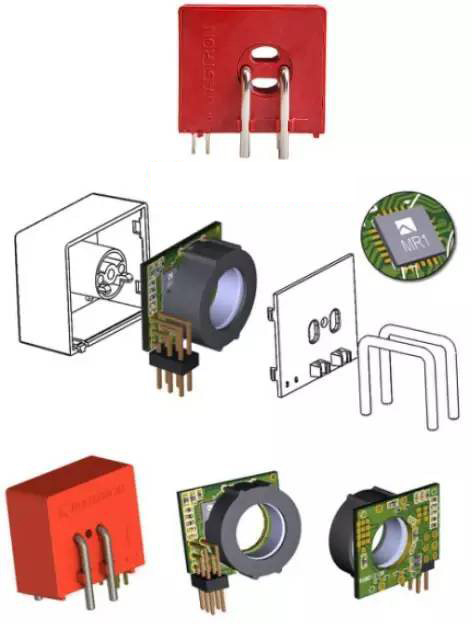

In order to meet such technical development requirements and structural design requirements, an intelligent ac/dc leakage current sensor with self-checking function, high precision, low power consumption, ultra-small size (26mm*23mm*12mm), pcb installation and no threading is introduced. rcmu101sm series products. The specific details are as follows:

· Safety self-check (self-check) function, safety level

· Leakage current detection range ac/dc 0ma~500ma

· Built-in single-chip integration solution

· Ultra-small size, pcb installation

· rcmu of type b

· dc~700hz frequency range

· High linearity and high precision in all temperature regions

· Single power supply

· Simple output application circuit

4. The importance of intelligent self-check function to a safety monitoring device

As a safety monitoring device, only when the safety monitoring device itself is guaranteed to function properly, can it provide safety monitoring for the entire system. So the self-check function is essential!

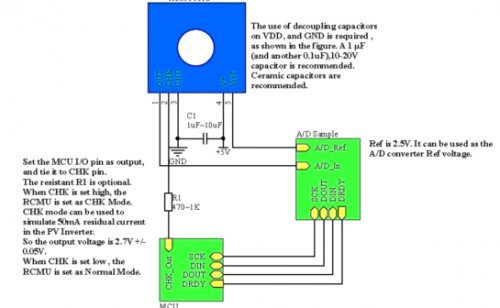

Introduction of product self-checking function

Figure 4)

During each power-on process, set the check pin to a high level of 3.3v

5. Intensive, modular and miniaturized rcmu

The leakage current sensor, in addition to using a single soc chip solution to achieve high integration and miniaturization (26mm*23mm*12mm), also has an ingenious design for the appearance and structure of the device, as shown in Figure (5):

This product uses the world's first single-soc chip design, has unique digital programming, high linearity and intelligent correction, unique self-check self-checking function, and can detect AC and DC leakage as low as 6ma, which fully conforms to power engineering. Testing requirements for DC power supply equipment.

6. Summary

The leakage current sensor launched by the soc chip solution based on ifluxgate technology makes it possible to reduce the size of the DC power supply equipment in power engineering, improve the energy density, reduce costs, and improve the efficiency of modular design.

The introduction of leakage current sensors will greatly reduce the cost of system resource integration of power engineering DC power supply equipment. In line with the requirements of the State Grid, the development direction of the intelligent, intensive, modular and miniaturized power engineering DC power equipment system.

Post time: Oct-29-2022